The Restlessness of Objects

Choreographing fulfillment

Jesse LeCavalier

On 25 October 2010, in the atrium of Beijing’s Viva Shopping Mall, a group of thirty performers dressed as UPS drivers and customers spontaneously broke into a series of choreographed dance numbers to a modified version of “That’s Amore.” UPS organized this bit of publicity as part of its “We ♥ Logistics” campaign, designed by Ogilvy & Mather and launched in 2010. Lauren Zhao, one of UPS’s general managers in Northern China, explained: “Having worked at UPS for more than ten years, this is the first time I have seen what we do—logistics—represented as a dance routine.”[1] In addition to such events, UPS has launched a range of TV spots that show their shipping and transport operations traversing a frictionless globe to the delight of their customers, also to the tune of “That’s Amore” but with modified lyrics. For example, the original line “When the world seems to shine / Like you’ve had too much wine / That’s amore” gets updated to “When technology knows / Right where everything goes / That’s logistics.”[2] In the commercials, UPS is represented by a large golden arrow tracing its way along recognizable urban infrastructures and by its workers as they glide over omnidirectional warehouse floors and slip through Venetian alleys.

As marketing campaigns go, selling logistics is a challenging exercise and the performance in Beijing is an effort to humanize what is largely a technologically driven field. In fact, the choice of words by UPS and Ogilvy & Mather reveals some of the difficulties that lurk in trying to understand something like logistics. Instead of letting it remain in the domain of technocrats and engineers, UPS tries to animate it and to personalize it, even to make it loveable. UPS is not expressly stating that they are good at logistics—that is, they are not making any of the more standard claims of authority. Rather, they present themselves as devotees and are happy to count instead the many ways they love logistics: “We love its precision, its epic scale, its ability to make life better for billions of people. Each day, our customers count on us to choreograph a ballet of infinite complexity played across skies, oceans and borders. And we do. What’s not to love?”[3] In addition to framing their concern around love of, affection for, and commitment to logistics, the suggestion that UPS is a choreographer also reveals the need to make sense of an industry that has no fixed form, no real image, and is largely communicated in systems illegible, if not incomprehensible, to humans.

With its roots in the military, logistics anchors the management trio that also includes strategy and tactics, and concerns the infrastructure of an operation: the three m’s of materiel, movement, and maintenance. Logistics has also been called “the art of defining and extending the possible” for its capacity to overcome unexpected challenges or to push at the edges of feasibility.[4] Logistics, in this way, is a world-making enterprise that emphasizes awareness, foresight, and preparedness; it requires a tactical mindset that accepts that things do not always go according to plan. The latter is a reality of military operations but, for UPS, acknowledging the likelihood of disruption is not an attractive selling point. Hence the company’s efforts to conjure the image of the choreographer, a figure associated with detailed knowledge of, and power over, the entirety of the operation at hand. The claim that each day UPS “choreograph[s] a ballet of infinite complexity” is an effort to insist that their logistics is not a reactive enterprise but is part of a regime of total awareness and control, a new kind of hyper-management.

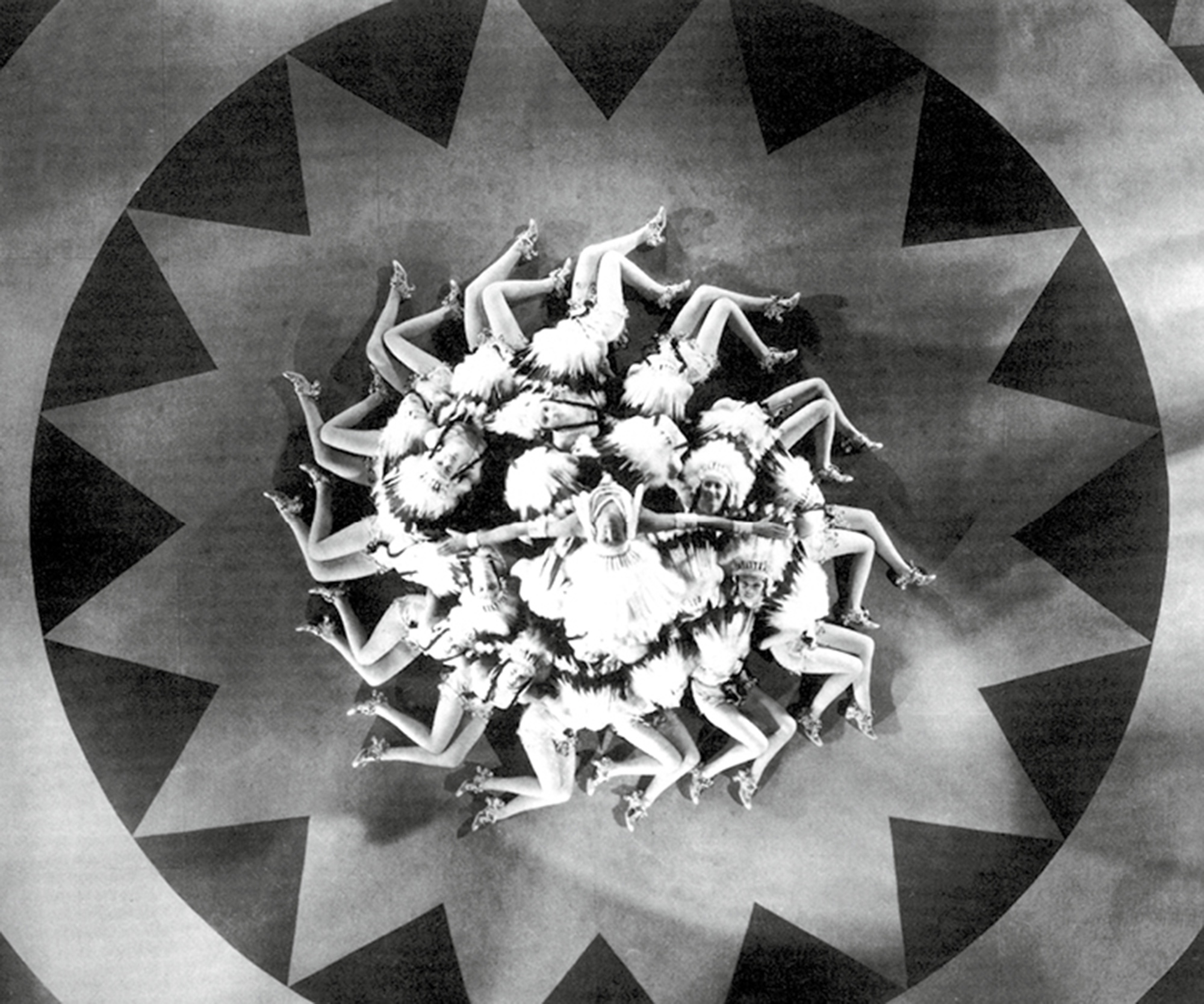

In case its claims to be a global choreographer were not broadcast loudly enough, UPS’s Beijing performance reiterates the message in the most literal way. Much of the footage from the UPS dance routines in Beijing is filmed from above, allowing viewers to witness the dynamic forms produced by the assemblage of bodies. Such images cannot fail to invoke the more spectacular dance numbers in the musicals of Busby Berkeley, especially his work for Warner Brothers in the early 1930s including 42nd Street, Gold Diggers of 1933, and Dames. Berkeley’s work is characterized by the precisely coordinated organization of battalions of showgirls to create dazzling geometric effects. Often shot from above using specially designed armatures, the hordes of dancers are transformed, with the help of elaborate stage mechanisms, into kaleidoscopic displays of bodies. For example, “I’m Young and Healthy” from 42nd Street uses a patented, segmented turntable stage to transform its performers into efflorescent cogs and whorls, simultaneously mechanical and botanical. Choreography for Berkeley amounted to an exercise in control in which every piece, whether human or non-human, is accounted for with exacting measure. For example, in preparation for the film Waterfall, Berkeley instilled discipline in his performers by relentlessly mapping out the routines through drawing: “In the first two days of rehearsal, before the Berkeley girls entered the pool, they studiously watched Buzz at the blackboard where, like a football coach, he white-chalked the patterns and movements the girls would undertake in the pool.”[5] Choreography here is thus associated with awareness of the time and the space of each piece, but also with notation. In the same way that Berkeley would trace out the paths of his dancers, so too do the arrows of UPS’s advertisements inscribe their objects’ trajectories on the space of the city. Perhaps not coincidentally, the composer who worked most closely with Berkeley in these years was Harry Warren, one of Hollywood’s most prolific and successful songwriters and, as it turns out, the composer of “That’s Amore.” While the connection may be distant, the links between Berkeley’s regimented choreography, Warren’s song, and UPS’s new campaign trigger a longer story about just what logistics is, what it does, and what love has got to do with it, anyway.

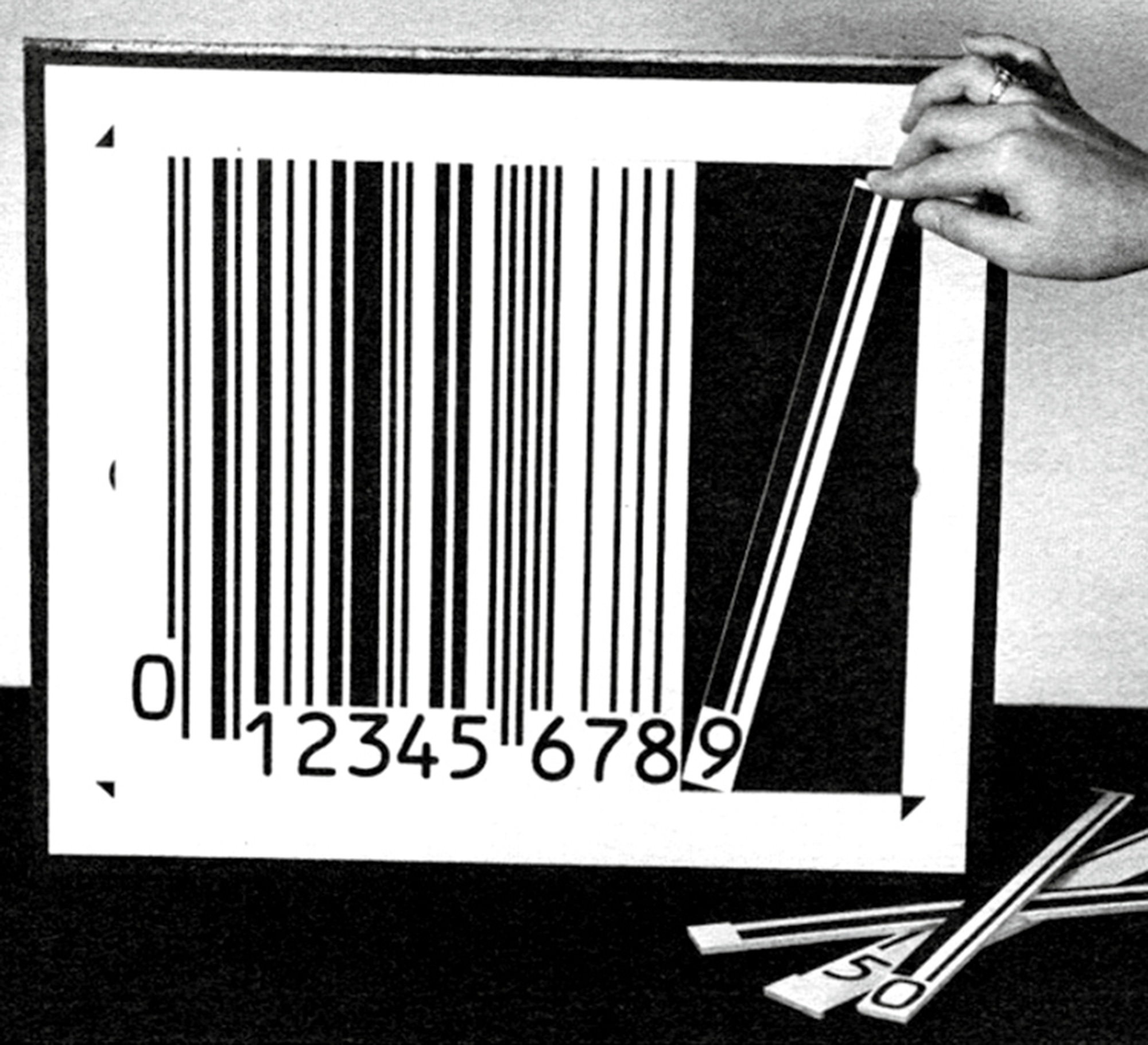

In the UPS television ads, amid the strains of “That’s Amore” one can discern the chirps of bar codes being scanned as the camera pans over boxes in motion. The bar code symbols themselves are superimposed over the objects, suggesting a new vision that will attend the new logistics promised by UPS. Bar codes are machine-readable symbols that translate a string of numbers legible to humans—in this case a product code—into a string of bits legible to computers. Different standards govern bar codes but in retail, at least, it is the Universal Product Code (UPC) that is most common. The first product ever to be recorded using a bar code and scanner was a ten-pack of Juicy Fruit chewing gum, purchased for $0.67 on 26 June 1974 in Troy, Ohio at 08:01.[6] The specific information attached to this transaction reflects the bar code’s ability to instantly record precise spatio-temporal data. Moreover, the bar code is one of the first symbols designed for computers to be read by computers. In order to better visualize the structure of the bar code, one can separate it into smaller bundles, each containing one number and eight bits. Each number is composed of a sequence of ones and zeroes, represented as solid or as void. With practice, one might come to more easily recognize the fortified “01111101” of the three or the wispy “10001000” of the eight. But reduced to the size of a postage stamp, the difference between one number and the next becomes harder to parse.

The introduction of the bar code, like many logistical transformations to follow, was intended to increase the speed of the transaction while reducing the likelihood of mistakes. The bar code also has the added benefit of information and inventory coordination. Not only was the clerk suddenly freed of the task of manually inputting price information, so too were the stock keepers relieved of having to physically inspect their inventory. They needed only look at the compiled data generated by the day’s bar code scans. So while the bar code sped things up, it also transferred labor to customers. Simply by retrieving desired items and handing them to a cashier to be scanned (and paid for), shoppers became a store’s stockists and market analysts. Not only did they help manage and record inventory, they also helped the store better understand what people were buying. And in the retail context, this is what matters most. In fact, consumer desire, and the will to capitalize and manipulate that desire, remains the driving force behind the huge techno-spatial complex that comprises retail logistics systems.

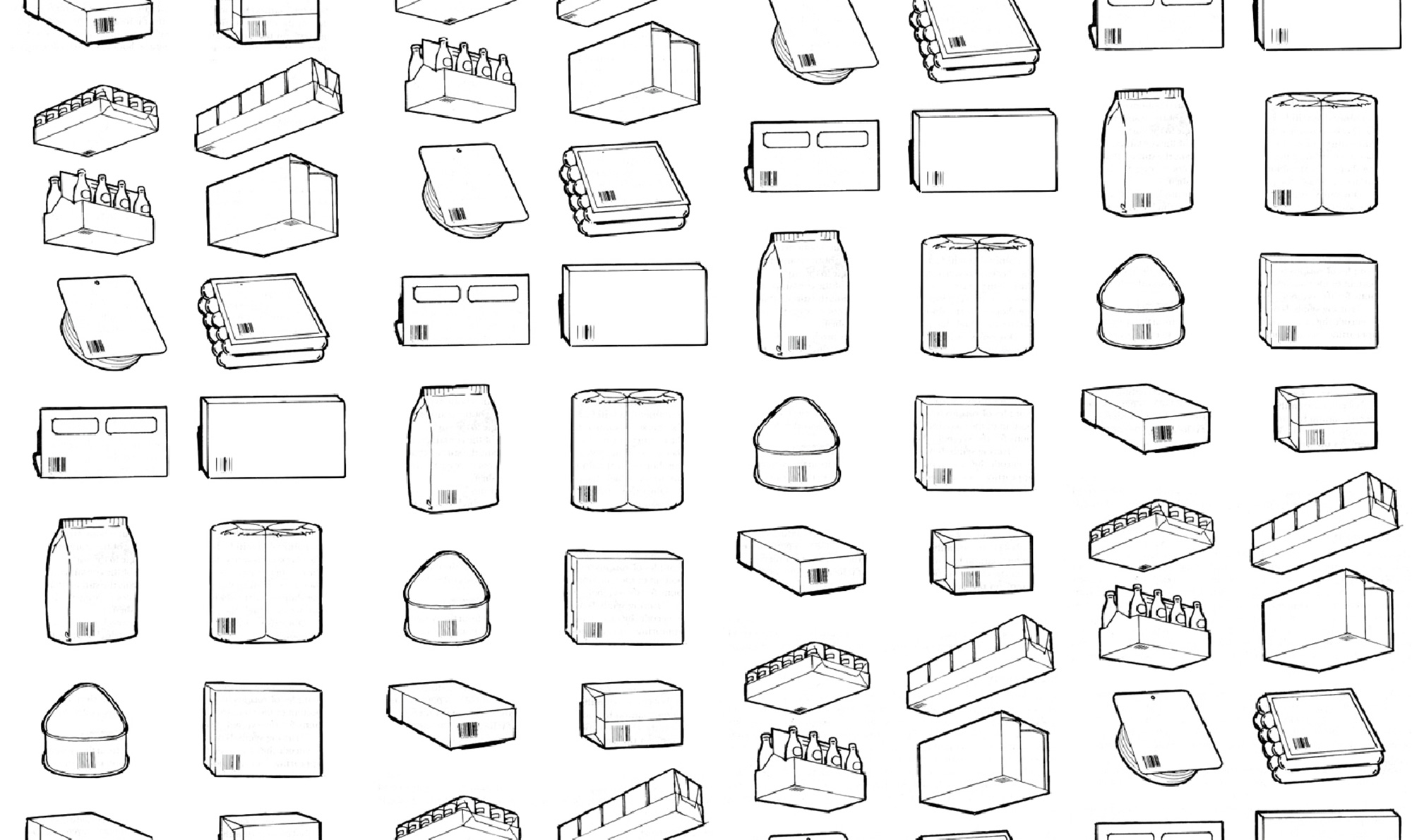

While the bar code is designed to be scanned easily and to reduce errors, it works best if placed in certain locations relative to the shape of the product it represents. This design consideration became acute when the symbol’s rapid implementation required it to be folded into the front-end manufacturing processes of all manner of goods. To resolve this, sets of guidelines were established to help producers figure out the best place on their products for their codes. A telling set of diagrams from a 1975 document about the UPC suggests ideal locations for bar codes on, for example, a six-pack of beer, an eight-pack of hotdogs, or a ten-pack of luncheon meat. In these diagrams, all the imagery relating to brand differentiation, the very stuff that wins the hearts and minds of customers, is conspicuously absent. The only mark on the products is the diminutive bar code. In the eyes of those responsible for circulating these objects, however, this is the only mark that matters for it contains all the necessary information, including the manufacturer, the name of the product, its price and—once it is scanned—information about its location in time and space.

The bar code for any given product is scanned at significant points along that product’s journey. For example, as it leaves a warehouse bound for a retail outlet, as it is received by its destination, as it is purchased at the checkout counter, etc. While the bar code cannot communicate the specific location in space and time of a product at any given moment, it can at least narrow the options down to being either in a certain general location or between two of them. This information allows inventory managers to maintain an awareness of the whereabouts of all their products. If their products have not yet arrived, managers can at least reassure themselves by knowing when they took leave of their former location. Moreover, in the eyes of inventory managers, the physical aspects of these products, numerous as they are, start to matter less than their schedules and locations. Inventory management, once concerned only with the physical handling of material, has increasingly become an exercise in information management as the objects themselves are reduced to and encapsulated by the bar codes on their surfaces. However, this spatio-temporal geography of objects is fleeting because by the time any one thing is scanned, it is already on its way elsewhere.

The obdurate materiality of inventory nonetheless remains and its stubbornness illuminates the tension between physicality and ephemerality at the heart of logistics. Managers want to move merchandise around as if it were only comprised of the bar code’s ones and zeroes, but the persistence of its substance requires a huge material apparatus to engineer its handling—replete with its own branch of science. These efforts bring with them new ways of perceiving location and distance, or even of understanding space. The bar code enables tighter control of an enterprise’s merchandise and allows it to further streamline its operations, making it “leaner” in logistics vernacular. When a bar code is scanned, a message is sent to coordinating software that maintains an overview of a given retail location’s stock of inventory. Once a certain product’s quantities dip past a certain point (a point calculated based on past and anticipated demand), a request is sent to the supporting distribution center (DC) to prepare more of that item for delivery. All of this is done in the hopes of minimizing the amount of time that any product is stationary, be it in the distribution center, on a truck, or on a shelf.

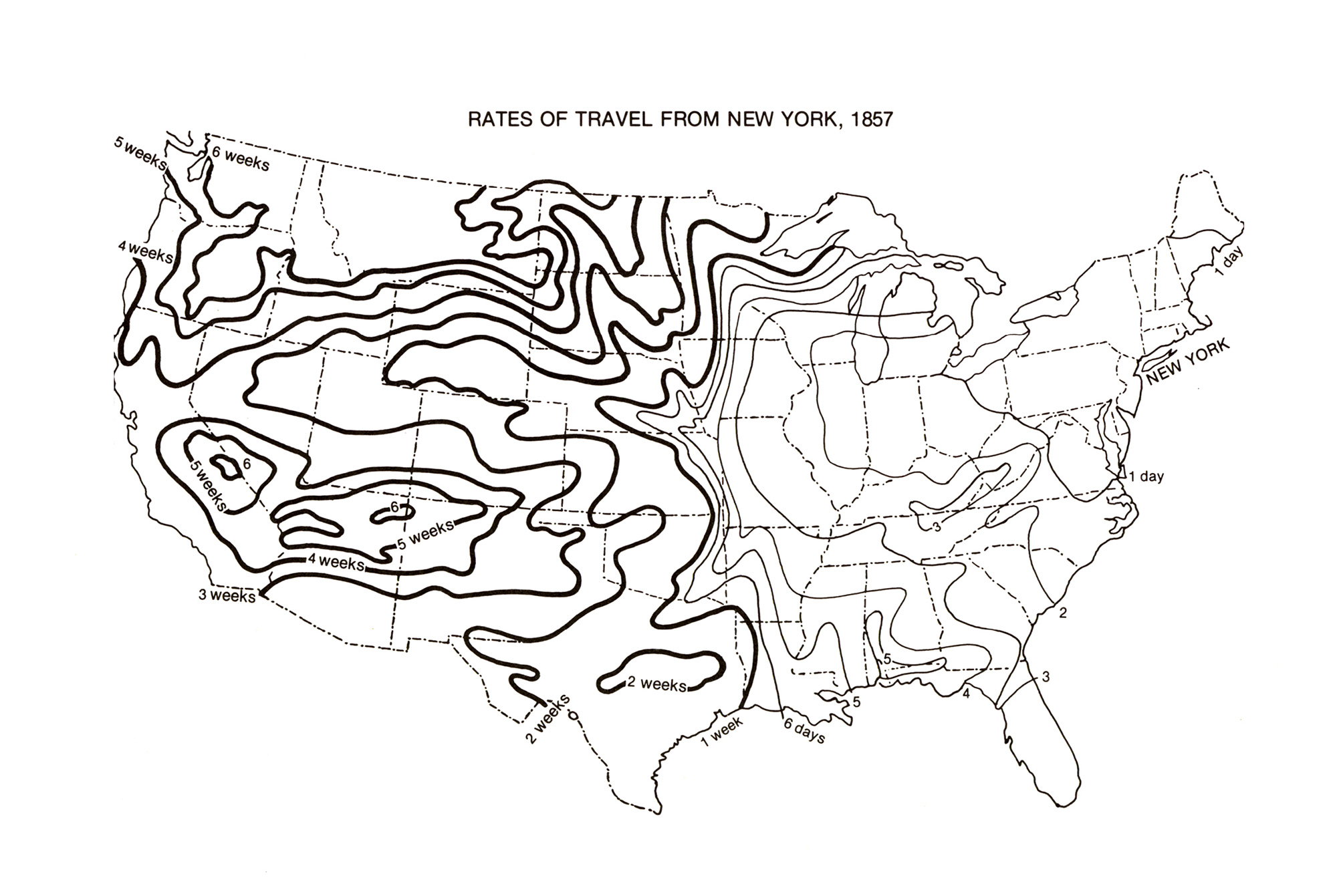

Distribution networks are measured in both miles and minutes. For example, the success of Walmart, one of the retail sector’s leaders in logistics, is based on founder Sam Walton’s early recognition of the importance of a nimble distribution system that would allow the frequent replenishment of inventory, even in small amounts. Walton and his planning team based the location of their distribution centers on a rule of thumb that stores should fall within a hundred-mile radius around a DC, but also that any round-trip from a DC to a store could be made in less than a day.[7] These parameters were flexible in order to accommodate the diverse transportation conditions in the rural areas in which Walmart first established itself. Such a mental overlay of time onto space is apparent in a much earlier map from Alfred Chandler, Jr.’s book The Visible Hand. Using what could be called “isotemporal” contours, the political map of the United States in 1857 shows travel time by rail to the rest of the country from New York City. Without showing any of the tracks or routes, privileged sites of access are apparent. For example, Chicago can be reached in less than two days while more proximate but less well-served destinations in Virginia will take upwards of four. More significant with a drawing like this is how it enables a particular way of viewing territory based on time rather than physical distance. Two destinations may be equally distant but transportation technology might render one of them twice as close.

Such an understanding of territory is further enabled by the bar code’s capacity to map an object’s location range. Based on assumptions about the regularity of travel time, retailers can plan for replenishment runs and calculate the time of delivery with increasing precision. Walmart, for example, spaces its distribution centers at relatively consistent intervals and in close proximity to the interstate highway system, generating, at least in the eastern half of the country, a nearly continuous space of distribution coverage. The company’s distribution centers and the stores they support develop in a cyclical manner in which retail outlets are built around a distribution center until its capacity is stressed. As this stress begins to reach a critical threshold, a new center is built. Pressure is relieved, new retail stores can open in adjacent territory, and the cycle continues.

These distribution centers demonstrate the effects logistics will have on architecture as it brings with it a shift from buildings defined by prescribed, stable, and discrete envelopes toward a network of configurable, fluid, and connected interiors, tethered to each other through the constant shuttling of transport vessels. In Walmart’s case, merchandise is consistently on the move and the DCs enable this restlessness of objects. These expansive installations—typically over one million square feet in area—mainly comprise miles of conveyors and row upon row of high-density shelving. It happens that there is a perimeter defined by a thin envelope and a roof, but these elements are incidental to the purposes at hand. Moreover, the layout of each company’s distribution center functions like its fingerprint. Each one is different and each reflects the specific character of an organization. The conveyor spine connecting induction risers to feed conveyors of one center suggests a company dealing with varied inventory and rapid turnover. The manifold shelves and small number of docks of another indicates inventory of a more specialized nature. The towers of small containers of a third indicate a company specializing in large objects whose size makes stacking them the most economical storage configuration. In all cases, the distribution center is a highly specialized custom-designed thing, ambiguous in its boundaries, behavior, and operation. These hybrid spaces also require a special kind of operator to work them.

In the context of retail logistics (including e-commerce), the task of a worker in one of these distribution centers is to assemble orders of merchandise destined for specific retail outlets. Goods are delivered from suppliers to the DC and stored in specific locations. DC operators are charged with “picking” items on a manifest issued by the DC coordinator. There are different versions of this but basically it amounts to taking homogeneous input sent from a supplier (e.g. cases of staplers) and assembling a heterogeneous output to be sent to a store based on its specific product mix requirement (e.g. one case of staplers, one box of pens, a single office chair, etc.). These lists vary from day to day and depend on a number of factors, including customer demand, sales projects, and even the weather.[8]

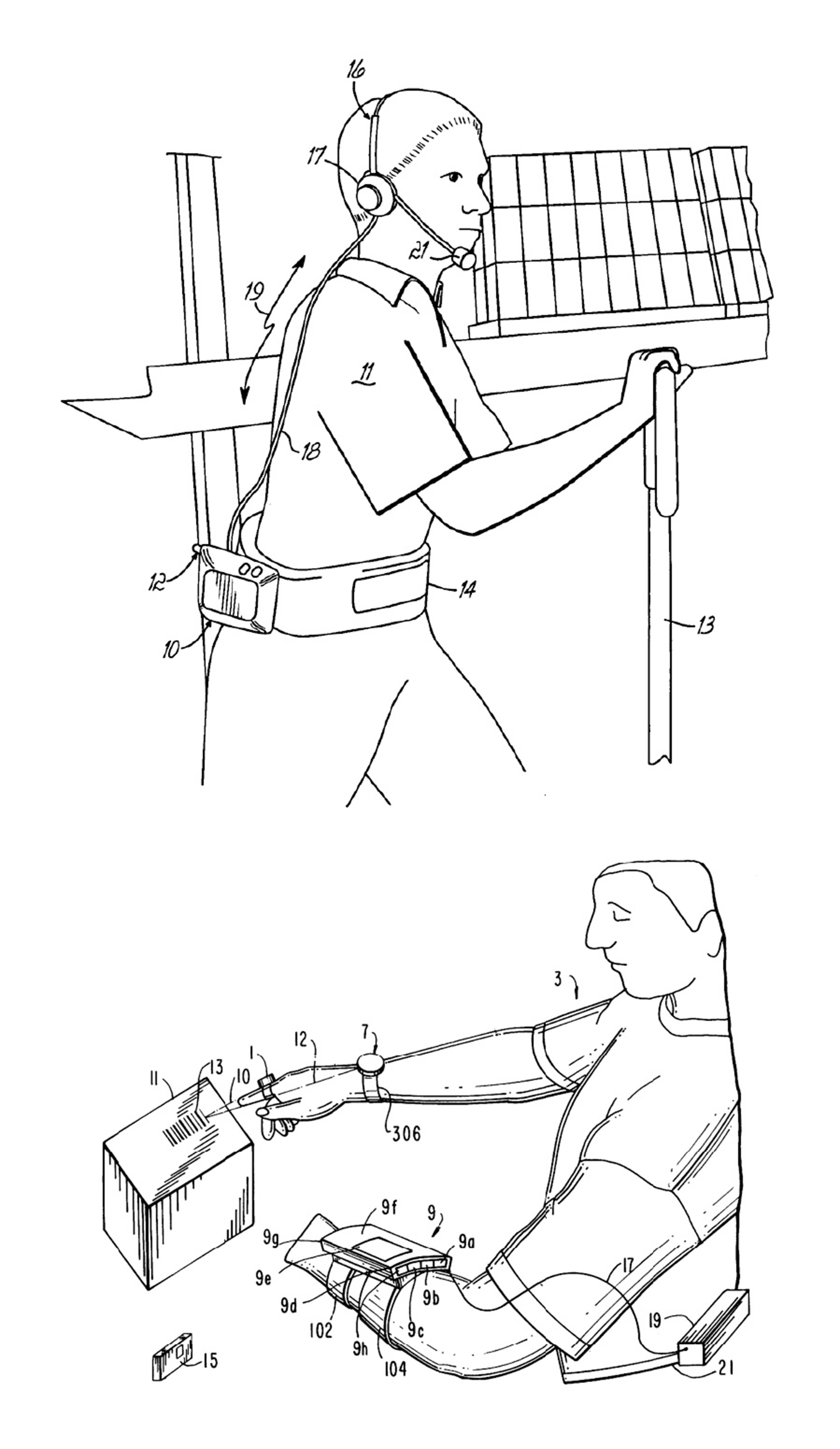

There are different ways to assemble these orders. The simplest way is also the slowest, in which a DC worker gathers a list of items by walking to each one’s location. Before the bar code was implemented, workers would enter all their data manually, writing down product names, quantities, etc. The bar code accelerated this process but also shifted power to the control system charged with coordinating the enterprise. The bar code allows things to be easily scanned but, as a result, the nature of the objects is abstracted and mediated through this computer language. Only the scanning technology is capable of reading them, especially at the pace demanded of rapidly accelerating logistics spaces. Increasingly, DC operators use a system often referred to as “hands-free” because the scanning component of a wearable computer system is physically attached to their bodies. On one hand workers wear a scanning “ring” that records the bar codes and on the opposite forearm, a digital display that shows the product’s information and also prompts the next item on the order. Meanwhile, the items being picked are physically moved on to a conveyor or into an intermediate container, often called a “tote,” to be later assembled into a larger order. With this approach, workers’ hands are free to handle merchandise more easily but they are unable to put their scanning tools down. “Hands-free” means wired in.

The next step in the development of such systems is the elimination of the readout altogether. If workers can be freed of the requirement to be constantly checking a screen, the thinking goes, they will be able to do their jobs faster and with fewer errors. The technology that allows this is called voice-directed picking and it replaces the visual manifest with an audible one that is broadcast to headsets worn by DC workers. Software translates order requirement data into synthesized human speech that directs the picking, packing, and shipping work. Voice-directed picking is deemed much faster because the pickers can be locating orders while communicating their location and actions via the headset’s microphone. Because operators need not check their lists constantly, this system is also referred to as “eyes-free.”

Some companies are trying to humanize the synthesized verbal commands in voice-directed picking. The company Lucas Systems, Inc., in partnership with Motorola, has developed a voice-directed picking system they refer to as Jennifer™ VoicePlus. Not only is the system of software, voice synthesizers, receivers, and scanners humanized, it is also gendered. One employee gushes, “You just have to listen to where Jennifer tells you to go, go get the product, and put it in the tote. There’s no way of making errors with Jennifer because you give her a number that tells her that you’re at the right location.”[9] This step in location confirmation is one means of the sustained feedback necessary in a picking system like this. Jennifer’s voice has a metallic shimmy as it breathlessly relays strings of numbers, verifications, questions, or commands. As speed remains an obsession, the voice playback is accelerated, almost eliminating the pauses between words. Here is a sample exchange between an employee (E) and Jennifer (J):

J: Sixonethreefour.

E: Nine four three.

J: Pickoneinnerpackofsix.

E: Grab one.

J: Oneinnerpackgrabbed. Pickthreeeach.

E: Grab three.

J: Bravo, putfiveeach.

E: Eight seven, put five.

J: Alfa, puttwoeach.

E: Five eight, put two.

J: India, puttwoeach.

E: Seven zero, put two.

J: Sixonethreeone.

E: Seven six four.

J: Pickoneeach.

E: Jennifer, what is item.

J: Itemonezerozerofivesixeightninesix.

E: Grab one.

J: Bravo, putoneeach.

E: Eight seven, put one.[10]

This seemingly nonsensical conversation is a precisely encrypted exchange but also a training session as Jennifer directs the employee to operate in a more machine-like way. Such feedback mechanisms are familiar tools of the disciplined institution, from Robert Owen’s experiments in self-assessment to the scientific management of a Taylorist shop floor to the cybernetic entanglements articulated by Norbert Wiener. However, the feedback in this case is not a matter of reciprocal calibration but a unilateral and ceaseless stream of numbers posed as questions and correctives. If the wearable scanners help to see like a computer, voice-directed picking helps to operate like one.

In a further step of amputation, after giving up eyes and hands, mobility itself is given over to the picking system in what is referred to as a Man-on-Board Automated Storage and Retrieval System (ASRS). Such an approach is particularly well suited to high-density fulfillment centers and consists of small platforms mounted to cranes that move along tracks in two axes. This allows workers on board to reach the tops of very high shelving units to assemble their orders. The automated dimension to this form of picking is through the movement itself. Workers do not steer the crane but are brought to each location directly in order grab the right eaches, innerpacks, or cases to fulfill their orders. With Man-on-Board ASRS, a single worker can quickly cover one large, tall aisle, gliding from point to point, just as their colleague in the next aisle is doing, and the next, and so on to the end of the racks.

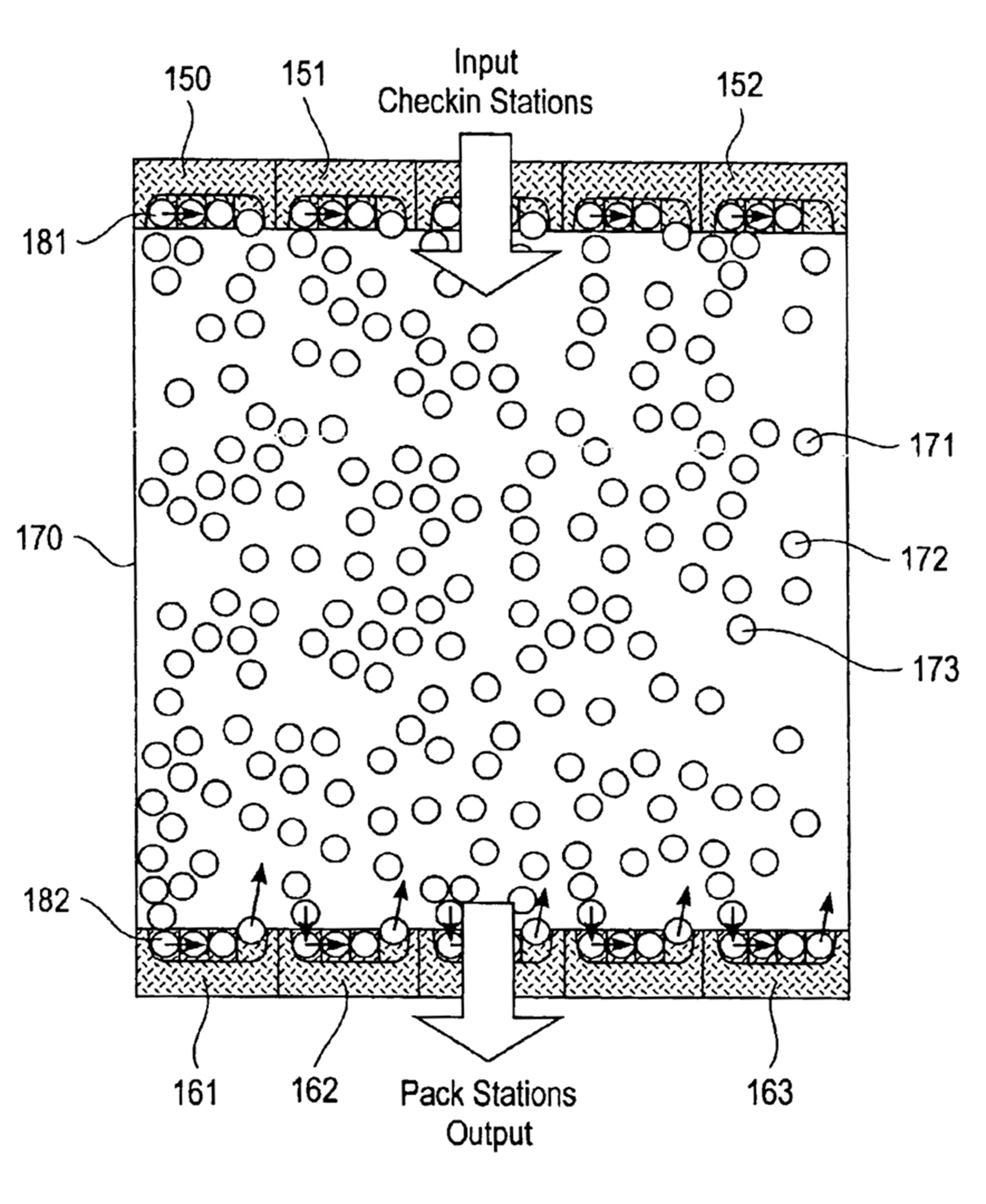

Bottom: Scanners can also be worn on the body. This drawing for Motorola’s US patent no. 5898161 (27 April 1999) highlights features of this system, including the ring used to scan bar codes and the readout attached to the forearm.

Rather than bringing people to the objects, a company called Kiva has figured out a way to use their system to bring objects to people.[11] Kiva’s approach replaces conveyors with small robotic drive units (RDUs) that transport “inventory pods” to a picking station, where a worker takes items from one rack and puts them on another, eventually to be packed and shipped. The robots are controlled by a series of inventory algorithms that search for the required inventory pod and direct the nearest robot to it. A grid of two-dimensional bar codes on the floor of the space provides checkpoints for the robots and controls their movements to ensure a smooth flow of traffic to the picking stations. As opposed to the conveyor-based model in which inventory is hierarchically managed and placed in predictable locations, the objects in Kiva’s system have no fixed location. Because the RDUs can reach any point in the warehouse, and because the movement can be calibrated to eliminate traffic interference, the distribution of goods in the warehouse floor is constantly changing based on what customers are ordering. But neither is the organization of the floor random—to speed up the process, the most desirable inventory is kept close to the picking stations while the rest is gradually pushed to the edges.

The logistics paradigm of inventory systems based on conveyors and regulated by bar codes like the UPC might be deemed “notational” for their concern with controlling the exact paths of things through space and time. Notational logistics relies on routine: objects follow the same path over and over again. In this sense, UPS’s claim to be a choreographer holds, so long as they are referring to this kind of logistics. However, while no less concerned with getting inventory from one place to another, the logistics of the two-dimensional bar code could instead be called “algorithmic” because it controls operations through formulae contingent on the specific requirements at any given moment. And, in spite of its claims to be a choreographer, much of UPS’s logistics practices are in fact more concerned with establishing the basic performance conditions that ensure an object’s arrival from one point to another and have less interest in controlling the specific nature of each journey.

The distinction between these two forms of logistics helps to puzzle through some issues in the current state of the field. Notational logistics follows a deductive, top-down route in which a plan is designed and executed repeatedly. With an algorithmic logistics, certain constraints are determined but the process is allowed to unfold in unanticipated ways, perhaps even ways that exceed the intuition of the designers. In a Kiva warehouse, for example, what seems like a chaotic jumble makes total sense to the computer systems organizing it. However, for all the sophistication behind the design of such a responsive system, the form and performance of the distribution center floor is based on one of the most fickle and irrational of principles: love. That is, the fluid constitution and configuration of the inventory is a dynamic index of consumer desire mediated through the bar code and mapped onto space, all fueled by extensive transportation and information networks. Logistics, in other words, underpins this apparent pursuit of happiness.

But does the ability to get the things we want faster and easier actually make us happier? In the emerging field of Happiness Studies, measures of happiness can be divided into three basic categories: “momentary feelings of joy and pleasure, … overall contentment with life, … [and] the quality of life achieved by developing and fulfilling one’s potential, which has been called eudaimonia or ‘the good life.’”[12] While conclusions that “individuals tend to make systematic errors when choosing between alternatives”[13] or that “happiness in the sense of subjective well-being doesn’t seem to rise systematically with income”[14] might seem obvious, their emergence within institutional discourse is significant. After all, the “pursuit of happiness” is inscribed as an inalienable right in the Declaration of Independence and forms a fundamental feature of economic identity in the US. Even more, mainstream economics still largely assumes that consumers behave to “maximize utility and that utility increases with the individual’s consumption.”[15] Such a belief has allowed economic growth to become a major policy imperative—enabled and reinforced by the logistics systems discussed here. However, if the findings from Happiness Studies were to have some influence, these policies and their attendant logistics networks might change, triggering subsequent transformations in the ways consumable items are bought, sold, marketed, measured, and managed. Contemporary algorithmic logistics orchestrates hedonic landscapes of desire as customers pursue happiness. Could logistics also play a role in the development, instead, of a eudaimonic landscape, a landscape of fulfillment, of love? We might have to change the song though: “When technology knows / Right where everything goes”—that’s not logistics—“that’s ah-MOH-reh!”

- Promotional video related to the Beijing performance on UPS’s official YouTube channel “Logistics: Live in Beijing (Behind the Scenes).” Available at youtu.be/GpDAYWDxiI0 [link defunct—Eds.].

- “We ♥ Logistics” commercial. Available at youtube.com/watch?v=mRAHa_Po0Kg [link defunct—Eds.].

- Official description accompanying select UPS commercials on the company’s YouTube channel. For example, see youtube.com/watch?v=mRAHa_Po0Kg [link defunct—Eds.].

- James Huston, The Sinews of War: Army Logistics 1775–1953 (Washington, DC: Office of the Chief of Military History, United States Army, 1960), p. viii. Huston’s reference is to a statement attributed to Otto von Bismarck that “politics is the art of the possible.”

- Jeffrey Spivak, Buzz: The Life and Art of Busby Berkeley (Lexington: The University Press of Kentucky, 2010), p. 91.

- This inaugural ten-pack is enshrined in the Smithsonian’s National Museum of American History. See, for example, James Surowiecki, “EZ Does It” in the New Yorker, 8 September 2003.

- Sam Walton, Walmart founder and former CEO, describes the process of opening stores: “We figured we had to build our stores so that our distribution centers, or warehouses, could take care of them, but also so those stores could be controlled … each store had to be within a day’s drive of a distribution center.” Sam Walton with John Huey, Sam Walton, Made in America: My Story (New York: Bantam, 1992), p. 141.

- For example, the company Weather Trends International sells weather analysis forecasts to retailers to help them plan their merchandising efforts accordingly. The company points out that small changes in temperature from year to year can influence consumer spending significantly. According to the website, “+1° HOTTER = +13% more HEDGE TRIMMER products sold each week,” while “+1° COLDER = +25% increase in MOUSE TRAP products sold each week.” The list is quite extensive. Available at wxtrends.com/retailers-suppliers.

- “Voice Picking at Do it Best With Jennifer and Motorola MC9000.” Available at youtu.be/t7-Vlf47raA.

- “Voice picking at The Container Store—B2C Fulfillment.” Available at youtu.be/alsdU0sR8jQ.

- The short story “The Machine Stops,” written in 1909 by E. M. Forster, addresses a number of themes apparent in contemporary logistics systems. Early in the story, one of characters derisively acknowledges that “of course she had studied the civilization that had immediately preceded her own—the civilization that had mistaken the function of the system, and had used it for bringing people to things, instead of for bringing things to people.”

- Daniel Nettle quoted in Bruno S. Frey et al., Happiness: A Revolution in Economics (Cambridge, MA: MIT Press, 2008), p. 5.

- Ibid., p. x.

- Amitava Krishna Dutt and Benjamin Radcliff, eds. Happiness, Economics, and Politics: Towards a Multi-Disciplinary Approach (Northampton, MA: Edward Elgar, 2009), p. 9.

- Ibid., p. 8.

Jesse LeCavalier is assistant professor of architecture at the New Jersey Institute of Technology. He was a researcher at the Future Cities Laboratory at the Singapore-ETH Centre for Global Environmental Sustainability in 2012 and was the 2010–2011 Walter B. Sanders Fellow at the University of Michigan’s Taubman College.