Whitewood under Siege

On the front lines of the pallet wars

Jacob Hodes

There are approximately two billion wooden shipping pallets in the United States.[1] They are in the holds of tractor-trailers, transporting Honey Nut Cheerios and oysters and penicillin and just about any other product you can think of: sweaters, copper wire, lab mice, and so on. They are piled up behind supermarkets, out back, near the loading dock. They are at construction sites, on sidewalks, in the trash, in your neighbor’s basement. They are stacked in warehouses and coursing their way through the bowels of factories.

The magic of these pallets is the magic of abstraction. Take any object you like, pile it onto a pallet, and it becomes, simply, a “unit load”—standardized, cubical, and ideally suited to being scooped up by the tines of a forklift. This allows your Cheerios and your oysters to be whisked through the supply chain with great efficiency; the gains are so impressive, in fact, that many experts consider the pallet to be the most important materials-handling innovation of the twentieth century. Studies have estimated that pallets consume 12 to 15 percent of all lumber produced in the US, more than any other industry except home construction.[2]

Some pallets also carry an aesthetic charge. It’s mostly about geometry: parallel lines and negative space, slats and air. There is also the appeal of the raw, unpainted wood, the cheapest stuff you can buy from a lumber mill—“bark and better,” it’s called. These facts have not escaped the notice of artists, architects, designers, or DIY enthusiasts. In 2003, the conceptual artist Stuart Keeler presented stacks of pallets in a gallery show, calling them “the elegant serving-platters of industry”; more recently, Thomas Hirschhorn featured a giant pallet construction as part of his Gramsci Monument. Etsy currently features dozens of items made from pallets, from window planters and chaise lounges to more idiosyncratic artifacts, such as a decorative teal crucifix mounted on a pallet. If shipping containers had their cultural moment a decade ago, pallets are having theirs now.

Since World War II, most of America’s pallet needs have been met by several thousand small and mid-sized businesses. These form the nucleus of not just an industry, but a sprawling, anarchic ecosystem—a world, really, complete with its own customs, language, and legends, with a political class, with its own media. This world is known as “whitewood.” There are approximately forty thousand citizens of whitewood, ranging from pallet pickers (who salvage pallets from the trash) to pallet recyclers (who repair broken pallets and make them whole) to pallet manufacturers, pallet consultants, pallet academics, pallet thieves, and pallet association presidents. Whitewood includes people who crisscross the country selling pallet repair machinery, preaching the gospel of tools such as the Rogers Un-Nailer.[3]

Not all pallets belong to the world of whitewood. The most important other category—and whitewood’s chief antagonist—is the blue pallet. These blues are not just a different color; they are also built differently, and play by different rules, and for the past twenty-five years, the conflict between blue and white has been the central theme in the political economy of American pallets. The person most identified with this conflict is a soft-spoken, middle-aged man from Kansas named Bob Moore. Currently embroiled in a legal battle over a pallet deal gone bad, Moore is a singular figure in the industry and a magnet for controversy. When not in federal court, he can sometimes be found piloting a Mooney Acclaim Type S airplane, which he prefers, when possible, to flying commercial. The Mooney is a good place to concentrate, one imagines. And it is important to concentrate when plotting the future of pallets.

• • •

The origin of the pallet is unknown. Rick LeBlanc and Stewart Richardson, co-authors of the indispensable Pallets: A North American Perspective, believe that an early prototype was used to aid in the stacking of wooden barrels in a warehouse in Louisbourg, Nova Scotia, in the mid-eighteenth century.[4] But the story becomes more certain only in the early twentieth century, when a machine resembling a heavy-duty golf cart appeared on the American warehouse scene. It was called a “lift truck,” and it had a large iron spatula protruding from its front.

Various proto-pallets, or “skids,” were used in concert with these early lift trucks. Some of the skids were wooden; some were metal; some had little iron legs, which allowed clearance for the spatula. Eventually, the iron legs faded into history—too extravagant—and were replaced by a pair of wooden support beams, called “stringers,” which gave the skid about six inches of height. Then the spatula mutated into a two-tined fork, and the skid, responding in kind, grew a third stringer along its dorsal spine. Around 1925, the skid gained a set of bottom deck boards, below the three stringers, and with this, the pallet had achieved its modern form. Functionally, this new bottom deck stabilized the pallet, which prevented stacks of goods from crashing down in the warehouse. Aesthetically, the effect was striking: the pallet had become a thing, alive and whole.

Although the technology was in place by the mid-1920s, pallets didn’t see widespread adoption until World War II, when the challenge of keeping eight million G.I.s supplied—“the most enormous single task of distribution ever accomplished anywhere,” according to one historian—gave new urgency to the science of materials handling. During the summer of 1941, at Fort Wayne, Indiana, the army staged a field test of various materials-handling contraptions, and the pallet–forklift combo trounced the competition. The Quartermaster General ordered a million pallets, and the domestic pallet industry was effectively born.[5]

Military depots began by palletizing heavy, regularly shaped objects, such as tins of K-rations. But over the course of the war, these depots, facing shortages of time, space, and labor, brought more and more items under the regime of the pallet. The Quartermaster Depot in Jeffersonville, Indiana, which occupied ten city blocks, was particularly aggressive in this regard; during a six-month stretch in 1943, workers there discovered novel methods of palletizing mattresses, saddles, baled goods, pyramidal tents, and tanned cowhide, among other items. By the end of the war, Jeffersonville had palletized 98 percent of its stock.[6]

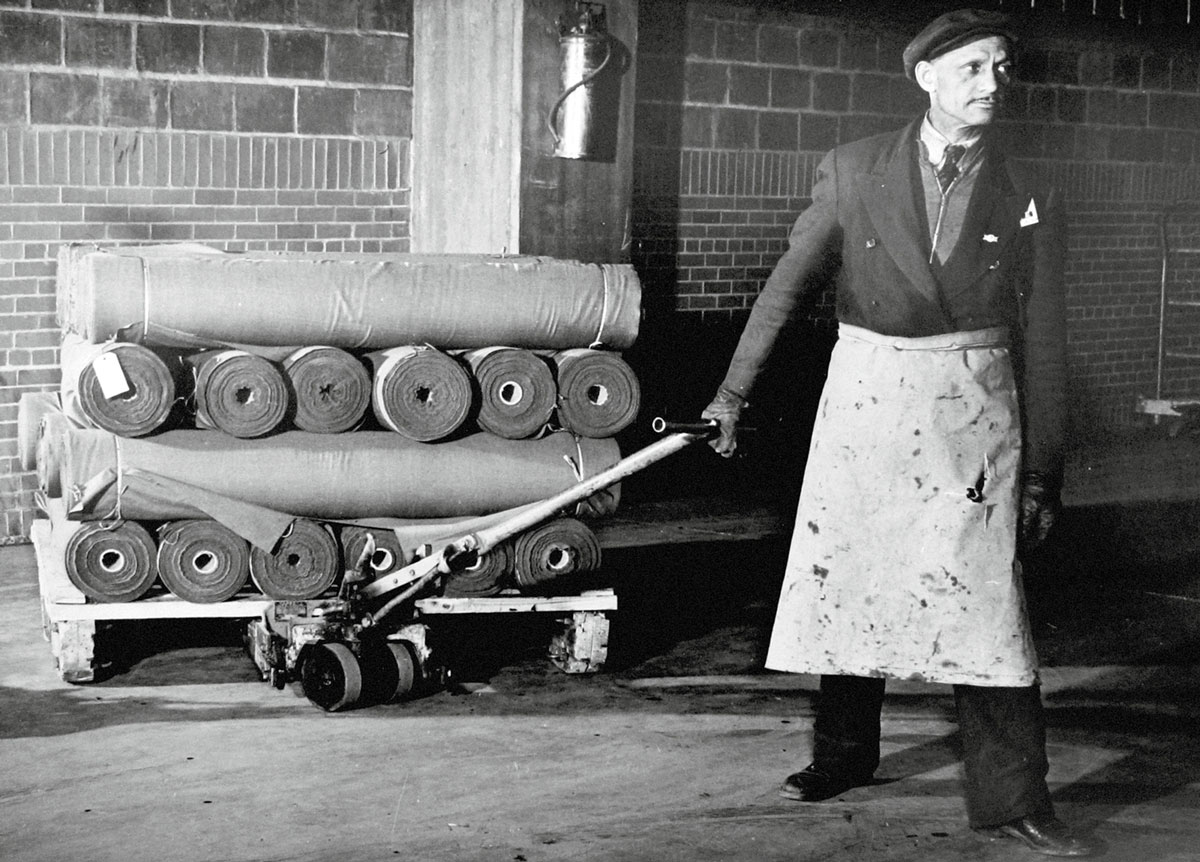

To get a sense of the productivity gains that were achieved, consider the canvas-like material known as duck. When an unpalletized rail car full of duck arrived at Jeffersonville, it required nine men, several four-wheel trucks, a forklift, and a warehouse mule to unload—a “long, involved process,” according to an item from the depot’s daily newsletter. The situation was “changed to a considerable degree” in October 1943, when a method of palletization was worked out that required fewer men, fewer machines, approximately half the time, and not a single mule.[7]

The pallet industry boomed after the war, along with interstate highways, long-haul trucking, and the rise of a national consumer culture. The canneries of the Salinas Valley were early palletizers, followed by other grocery sectors, then the auto industry, then everything. In 1954, pallet manufacturers left the country’s wooden box association and founded their own trade group, the National Wooden Pallet and Container Association, or NWPCA. Its slogan: “Pallets move the world.” Sometime in the early 1970s, on a CBS news broadcast, John Kenneth Galbraith informed Dan Rather that pallets were the second-fastest-growing industry in America. “What are those?” Rather asked. Or so the legend goes.[8]

The boom ultimately created a problem, because all of these pallets did not disappear when they reached their destinations. They piled up: on loading docks, in stockrooms, in landfills. Beginning in the late 1970s, people realized these used pallets might have value, and the pallet recycling industry was born. There was good money in recycling, especially in the early days. The supply of raw material was cheap, if not free, the capital investment was minimal, and the whole thing had an appealing simplicity: acquire pallets from wherever they end up, fix them up, sell them back to manufacturers. The service this new generation of recyclers provided was called “reverse logistics.”

Many of the early recyclers were truckers, garbage men, and others who worked in proximity to pallets. A young man named Ricky Mock got into the business in the winter of 1983, when he tired of chopping down oak trees on the family hog farm in Covington, Georgia, and saw an ad in the local newspaper advertising free pallets for anyone willing to cart them away. “I told my daddy, ‘We could cut up those pallets and make firewood out of them,’” Mock recalled. “‘We could use them to patch fences, and also to build gates, and do different things.’” Twenty-five years later, Mock had one of the largest inventories of recycled pallets in the country: three hundred thousand of them, maybe more, in stacks thirty or forty feet high, stretching over twenty-eight acres of concrete yard. It was a city of pallets.

The advent of recycling allowed the whitewood ecosystem to multiply in complexity. Recyclers arranged to leave empty trailers at the loading docks of their customers, who filled them with pallets and then called for a pickup. Meanwhile, individual pallet pickers began rescuing pallets from the trash and bringing them to recyclers, earning fifty cents or a dollar per piece. Higher up the food chain, pallet brokers fulfilled orders by aggregating shipments of pallets from smaller recyclers. A trade then developed between recyclers, who swapped pallets of different sizes and styles, and the graph of pallet movements became thick with arrows in all directions.

• • •

Blue pallets are an inch or so taller, often cleaner, and always more uniform than the pallets of whitewood. Crucially, blues do not have any stringer boards along their sides; instead, their height is obtained by way of nine wooden blocks sandwiched between the top and bottom deck boards. This block design allows forklifts and other tools to enter the pallet with equal ease from four directions. (Most stringer pallets, by contrast, offer either “two-way entry” or “partial four-way entry.”) There are approximately two hundred and forty million blue pallets in the world, circulating in over fifty countries. On the sides of each are the words, “Property of CHEP.”

CHEP, a subsidiary of Brambles Limited, an Australia-based multinational corporation, is the largest pallet business in the world. The company earned $3.5 billion in pallet-related revenues during fiscal year 2013, and in many markets has achieved pallet monopoly.[9] CHEP’s roots stretch back to World War II, when the American military shipped millions of palletized loads to Australia. At the end of the war, those pallets were abandoned, and CHEP was formed out of this accumulation. After four decades of growth and expansion, the company entered the US market in 1990, in what amounted to an obscure case of military blowback.

CHEP doesn’t sell pallets; it rents them. This means that, in contrast to the world of whitewood, where a pallet may change ownership many times, CHEP maintains control of its pallets throughout their lives. But the company’s experience operating what is known in the industry as a “closed pool” didn’t translate easily into the American context, where supply chains were longer, more complex, and geographically dispersed. In 1995, CHEP hired Bob Moore, who had worked as an executive at PepsiCo for the previous two decades, to take over its US operation. Moore wanted to grow, fast, and so he loosened controls on CHEP’s pool, and millions of blue pallets poured into the stream of commerce. After completing their journeys, however, a significant number of these pallets did not end up where they belonged, back at a CHEP depot. Instead, they ended up in the yards of whitewood recyclers.

Moore sent “asset retrieval specialists”—former cops, off-duty cops, muscle men—to visit recycling yards and demand the return of CHEP’s property. Ricky Mock, who had accumulated 40,812 blue pallets over a number of years, declined to turn these over to CHEP without what he considered adequate compensation. After all, he figured, he had not only paid for these pallets, he had also invested in their transport, sorting, and storage. (Like other recyclers, Mock buys used pallets by the trailer-load, which makes it difficult to purchase one kind to the exclusion of others.) There were letters from CHEP, phone calls, visits, more visits. “They decided they were going to put me out of business,” Mock told me. “They had spies, they hired detectives, and had them sit and watch my trucks, and when I was coming and going. They had guys that would come out and sit in the woods. We caught the guys coming out of the woods. Then they flew over with a helicopter.”

A court battle ensued. The helicopter allowed CHEP to produce aerial prints of Mock’s pallet yard, which were introduced as evidence at trial. The federal district court for northern Georgia remarked that CHEP went to “enormous effort and expense” to reclaim its pallets, “despite the undisputed fact that many of the pallets were in a greatly deteriorated condition.” Elton Potts, at the time CHEP’s senior vice-president for asset management, took the stand and explained, “We have used the phrase, ‘Never leave a pallet behind.’” Under questioning from the bench, Potts said that he would rather destroy a CHEP pallet than allow it to fall into the wrong hands. The jury determined that CHEP owed Mock more than half a million dollars—about $14 per pallet—for the return of its property. After CHEP appealed, the award was reduced to $5 per pallet, which still amounted to far more than CHEP had ever paid a recycler.[10] “We stood up for what is right for our industry,” Mock told the trade magazine Pallet Enterprise, which followed the trial closely. “We put our trust in God. Bathed it in prayer.”[11]

• • •

There were other battles—in San Antonio, a recycler who refused to hand over CHEP pallets was marched out of his yard in handcuffs, and had his forklifts impounded—and other trials, the results of which have not been entirely conclusive. Courts have generally affirmed CHEP’s right to reclaim its pallets, but the question of whether and how much to compensate recyclers depends on the specifics of the case and the particularities of state law. Currently, CHEP pays recyclers $1.25 for the return of a pallet, plus up to $1.75 more if the recycler transports the pallet to a CHEP depot.[12] Most recyclers grumble, but accept the arrangement. Unless they want to pick a fight, they have little choice: they receive blue pallets whether they want them or not, and if they sell them on the black market, or grind them into mulch, or do anything other than return them to CHEP, they are inviting the wrath of the company’s asset recovery team.

What is most vexing to many recyclers is the belief that the accumulation of blue pallets in their yards is not an accident, but a deliberate CHEP strategy. After all, collecting these stray pallets takes a lot of labor, a lot of miles, and a lot of trucks. If you are CHEP, why do this work yourself if you can get someone else to do it for you, at a price that you dictate? In 2008, a group of recyclers filed a class action lawsuit, claiming that CHEP was leveraging its dominant market position, and violating anti-trust law, by transferring its operational costs onto recyclers. The recyclers argued that CHEP had made them into a “conscripted collection army.” CHEP hired excellent lawyers, and the case was ultimately dismissed. Then and now, the company has maintained that its relationship with recyclers is mutually beneficial.[13]

A good place to study this dynamic is Hunts Point, an industrial neighborhood in the Bronx that happens to be the pallet capital of New York City. There are half a dozen recycling yards here, all within walking distance of a wholesale market where most of the city’s fresh food arrives. (This is no accident; if you are in a strange city looking for pallets, follow the groceries.) The yards are open to the sky, surrounded by high concrete walls, and filled with towers of pallets, which are arranged in clusters like groups of skyscrapers. The feeling is intensely architectural. All day, drivers zoom around on forklift trucks, moving stacks of pallets, and the towers rise and fall.

The larger yards have dozens of workers and various intriguing machines. One of the smaller yards, and the only one in the Bronx owned by a Dominican family, is Palletteen Pallets. Palletteen consists of a yard about half the size of a football field, a shed that serves as an office, a Snapple machine that sits on the sidewalk, on top of a pallet, and five pallet repair workstations, which are protected from the rain by corrugated tin roofs. The owner, Gabriel Solis, told me that business hasn’t been this bad in ten years. “The blues are a problem,” he said. “Plastic is another problem.”

Gabriel’s nephew Dari showed me his forklift truck, which had his name spray-painted across the back. He’s been moving pallets around, he told me, since middle school. All morning, trucks pulled up in front of the yard and disgorged pallets onto the sidewalk. There were some blues, a red—the property of a much smaller rental company, called PECO—and many varieties of whites, in various states of repair. Dari and his uncles whizzed about on their forklifts, slicing and dividing and recombining the stacks, until like was with like. At one point, Dari, Gabriel, and Gabriel’s brother Henry all had stacks of pallets balanced high in the air on their forks, and they converged to execute a three-way aerial sort. It was a forklift ballet. Henry looked over and winked.

Inside the yard, workers at the repair stations operated on whitewood pallets, prying off damaged boards and nailing down new ones. Dari kept tallies on a piece of cardboard. Each of these pallets would resell for somewhere between $2.50 and $5.00, he said, depending on its condition. As the day wore on, stacks of repaired pallets grew higher around each station. They had stray markings and bits of color: a thick blue line, a spray-painted pink “3.” The newer blond boards stood out against the old ones. One pallet had the words “Vincent Rutigliano Importer & Distributor of Italian Food Specialties” impressed on its side in an elegant script. These were the kind of pallets that Stuart Keeler would like, I thought: they were accreting history, and character, as they aged. They were palimpsests. Nearby was a stack of blues, blocky and uniform, waiting for a pickup by CHEP. If they had a history, it had been wiped clean, or painted over.

• • •

By 2002, there were ten million blue pallets floating around the US, unaccounted for, and a report by Credit Suisse warned investors that CHEP usa was experiencing “a loss of control of [its] pallet pool.”[14] Less than a month later, Bob Moore left the company.

Despite these lost pallets, CHEP continued to grow. In 2010, in a shock to the industry, Costco announced that it would only accept shipments on CHEP-style block pallets: they break less, they have tighter quality controls, and full four-way entry promises tiny but measurable efficiencies when loading and unloading trucks. Panic ensued in the world of whitewood. “If we don’t do something now, we are all going to be out of business,” John Swenby, the president of Paltech Enterprises, told Pallet Enterprise. Swenby and others have launched an industry collaborative, called 9Bloc, which aims to create a new, open pool of whitewood block pallets, with specs and quality control equivalent to CHEP’s. But because block pallets cost much more to produce than those made with stringers, the economics favor rental companies.[15]

Meanwhile, other disturbances threatened whitewood. In 2006, an upstart company called iGPS declared that the future of pallets had arrived, and it was neither blue nor white, but plastic. These plastic pallets were expensive to produce, but they promised to be strong, uniform, clean, and individually trackable by way of embedded radio-frequency identification, or RFID, tags. The man who had put together the business plan, sold it to investors, and now led iGPS was none other than Bob Moore.

Moore, in his new role, declared war on wood. iGPS commissioned studies that found that wooden pallets harbored E. coli and other bacteria, representing, in Moore’s words, a “pervasive threat” to the food supply. A series of incendiary press releases drove home the point. The president of the NWPCA at the time, Bruce Scholnick, was furious, and when the contamination of a Texas butter shipment made the news, he suggested that plastic pallets might be at fault. At this point, iGPS sued the NWPCA for defamation, and the mudslinging itself became newsworthy. “They are bullies,” Scholnick told the Wall Street Journal. “There is no question in my mind, they started it.” Websites of uncertain provenance, like PalletTruth.com, sprung up, warning the public that cribs made from pallet wood can poison your baby, and living rooms appointed with pallet furniture can spontaneously combust.

It now appears unlikely that iGPS will be the future of pallets. After fomenting a wave of concern about wood, spending half a billion dollars to build a pool of ten million plastic pallets, and winning accounts with General Mills, ConAgra, and other big manufacturers, iGPS proceeded to lose a million and a half of its pallets, RFID tags notwithstanding. Last June, the company declared bankruptcy. Moore, who was pushed out as CEO in late 2010, has for the past four years been engaged in a bitter legal dispute with the company’s investors. “You’re too old, Bob. You’re finished,” one of them allegedly told Moore, according to a court filing. “You will never work in this supply chain again.”[16]

• • •

I met Moore last summer, when he was in New York for a court appearance related to the iGPS controversy, and we talked for hours: about the pros and cons of southern yellow pine, about the time a typical CHEP pallet spends in what they call the “pallet hospital,” about how he once made a crazy, desperate move to save the Procter & Gamble account. He showed me images of a modular, hollow plastic pallet that a Canadian company is currently prototyping. It looked like a collection of brightly colored Lego pieces, with a suite of electronics hidden away in its guts. “This is the best pallet I’ve ever seen,” Moore said. “They want me in the worst way to launch this pool.”

But Moore doesn’t want to lead another plastic pallet company. Instead, he has a new plan, based on an idea he got years ago from a retired Australian racecar driver: take wooden pallets and coat them with a plastic resin. The resulting hybrid pallet, Moore said, will be cheap and easy to repair, like a typical wooden pallet, but without the downsides of wood. It won’t catch fire, for example, and it won’t “shed.” (When a piece of a wooden pallet sheds, or splinters off, it can bring an entire assembly line to a halt.) Ultimately, Moore told me, he expects his new, hybrid pool to comprise a billion pallets.

Rather than purchase a billion pallets, though, Moore plans—arguably for the second time—to harness the labor of whitewood and make it serve his purposes. He will sell recyclers buckets of resin, offering them the opportunity to transform their existing stock into the pallets of the future. Along with the resin will come a set of RFID tags. If all goes well, these will allow Moore’s new company, PalletWorks, to track the hybridized pallets throughout their lives.

Whether whitewood will become a giant, decentralized dipping station for Moore’s new project remains to be seen. For more than half a century, pallet futurists have announced the next big thing, only to see the basic wooden variety remain the workhorse of global logistics. “Lots of people have tried to invent a better pallet,” Robert Bush, a professor at Virginia Tech affiliated with the school’s Center for Packaging and Unit Load Design, told me. “We see them almost every day at our testing lab. But it’s harder than people think. It’s surprisingly hard. It’s one of those things that people got pretty close to right the first time.”

This does not necessarily help whitewood in its current predicament. Creating a viable pool of block pallets will be an uphill battle, requiring a high degree of coordination and major capital expenditures. Meanwhile, orders for new stringer pallets are down, and without a steady infusion of new pallets, the health of the entire ecosystem is suffering. Ricky Mock’s inventory is less than a tenth of what it once was. While no one expects whitewood to disappear anytime soon, it will probably continue to lose market share. Gabriel Solis, the owner of Palletteen Pallets, says that God will provide for all colors. Dari recently gave up his forklift, and has been looking for a job at UPS.

See press about “Whitewood under Siege” on The New Yorker, Late Night Live, RAGEMAG, NPR, and Longform.

- Estimates of the number of pallets vary, and none are precise. This number comes from Philip A. Araman, a researcher at the US Department of Agriculture’s Forest Service and the coauthor of a forthcoming statistical study of the pallet industry. In discussion with the author, 10 January 2014.

- James L. Howard and Rebecca M. Westby, “U.S. Timber Production, Trade, Consumption and Price Statistics 1965–2011, Research Paper FPL-RP-676” (Madison, WI: US Department of Agriculture, Forest Service, Forest Products Laboratory, 2013). Available at treesearch.fs.fed.us/pubs/43952 [link defunct—Eds.]. The figure here—15.6 percent of total lumber—includes a small amount of lumber used for shipping purposes other than pallets, such as dunnage. The 12 percent figure was extrapolated from an earlier Forest Service dataset by Mark White, a pallet consultant and director of the William H. Sardo, Jr. Pallet and Container Research Laboratory at Virginia Tech. See Warren F. Kruger, “White Paper on the Pallet Industry and Greystone Logistics,” undated.

- See the US Census Bureau’s revised “Statistics for Industry Groups and Industries” for the year 2011. Available at factfinder2.census.gov/faces/tableservices/jsf/pages/productview.xhtml?pid=ASM_2011_31GS201&prodType=table. The number for North American Industrial Classification System code 321920 is rounded down to account for the employees of PECO and CHEP’s US division, as well as those who manufacture other products aggregated under the same NAICS code, such as chicken coops, vegetable crates, and cigar boxes.

- Rick LeBlanc and Stewart Richardson, Pallets: A North American Perspective (Cobourg, Ontario: PACTS Management, 2003). LeBlanc’s backstory: “I was a schmuck supervising guys repairing pallets, and then I got really interested in them.”

- Alvin P. Stauffer, Quartermaster Depot Storage and Distribution Operations, Q.M.C. Historical Studies, no. 18 (n.p.: Historical Section, Office of the Quartermaster General, 1948), pp. 1, 101. Also see Erna Risch, The Quartermaster Corps: Organization, Supply, Services, vol. 1 [1953] (Washington, DC: Center of Military History, 1995), p. 351. Available at www.history.army.mil/html/books/010/10-12/CMH_Pub_10-12-1.pdf [link defunct—Eds.].

- David Spence Hill, “Supply, Stock Control, Storage: Jeffersonville Quartermaster Depot. An Interim Report of the Historical Project for the Army Service Forces in Four Volumes,” pp. 313–331, Mostly WWII Historical Studies of Select QM Depots and other Field Installations, 1943–1952, Records of the Office of the Quartermaster General, Record Group 92, National Archives at College Park, College Park, MD. The 98 percent figure is from a memorandum by Clifford W. Parham, Storekeeper, reproduced on pp. 431–432.

- David Spence Hill, “Supply, Stock Control, Storage,” p. 329. Incidentally, this may have freed the mules for service at the front. Although horses went out of fashion in World War II, with some mounted regiments going so far as to send their animals back to the US, mules proved unexpectedly useful in mountainous areas of the European theater, such as Sardinia, as well as in Burma. See Erna Risch and Chester L. Kieffer, The Quartermaster Corps: Organization, Supply, Services, vol. 2 [1955] (Washington, DC: Center of Military History, 1995), pp. 313–323. Available at www.history.army.mil/html/books/010/10-13/CMH_Pub_10-13-1.pdf [link defunct—Eds.].

- Rick LeBlanc and Stewart Richardson, Pallets, p. 43.

- Brambles Limited, 2013 Annual Report.. CHEP’s pallet revenue is calculated by subtracting IFCO PMS and LeanLogistics contributions from total revenues for Brambles’s pallet division.

- CHEPUSA v. Mock Pallet Co., No. 02-2053, slip opinion, pp. 6, 14 (Northern District, Georgia, 18 August 2006). Available at bitly.com/chep-v-mock.

- Chaille Brindley, “Mock Pallets Wins $584,000,” Pallet Enterprise, 2 June 2004. Available at palletenterprise.com/articledatabase/view.asp?articleID=1141.

- Chaille Brindley, “The True Cost of Pallet Logistics—Time for a Raise?,” Pallet Enterprise, 1 September 2013. Available at palletenterprise.com/articledatabase/view.asp?articleID=3999.

- Class Action Complaint, Best Pallets v. Brambles Industries, No. 08-2012 (Western District, Arkansas, 6 February 2008); available at bitly.com/pallets-class-action-complaint. Deposition of Marshall White at p. 127, Best, No. 08-2012 (Western District, Arkansas, 30 March 2009); available at bitly.com/pallets-class-action-deposition.

- Greg Ward et. al, “Brambles Industries: CHEPUSA—Broken or Damaged?,” 27 February 2002 company update by Credit Suisse/First Boston. Available at bitly.com/chep-credit-suisse.

- Chaille Brindley, “Pallet Industry Cooperative Leaders Answer Tough Questions,” Pallet Enterprise, 1 January 2012. Available at palletenterprise.com/articledatabase/view.asp?articleID=3570.

- Amended Complaint, p. 9, Moore v. iGPS Co., No. 651907/2011 (New York Supreme Court, 17 January 2012). Available at bitly.com/moore-v-igps-complaint. In addition to iGPS, the complaint names eighteen other persons and entities as co-defendants.

Jacob Hodes, a Brooklyn-based writer, recently completed his studies at the City University of New York’s Graduate School of Journalism. He is currently working on an essay about the difficulty of sermons.